Design and Prototype of ByteWrist

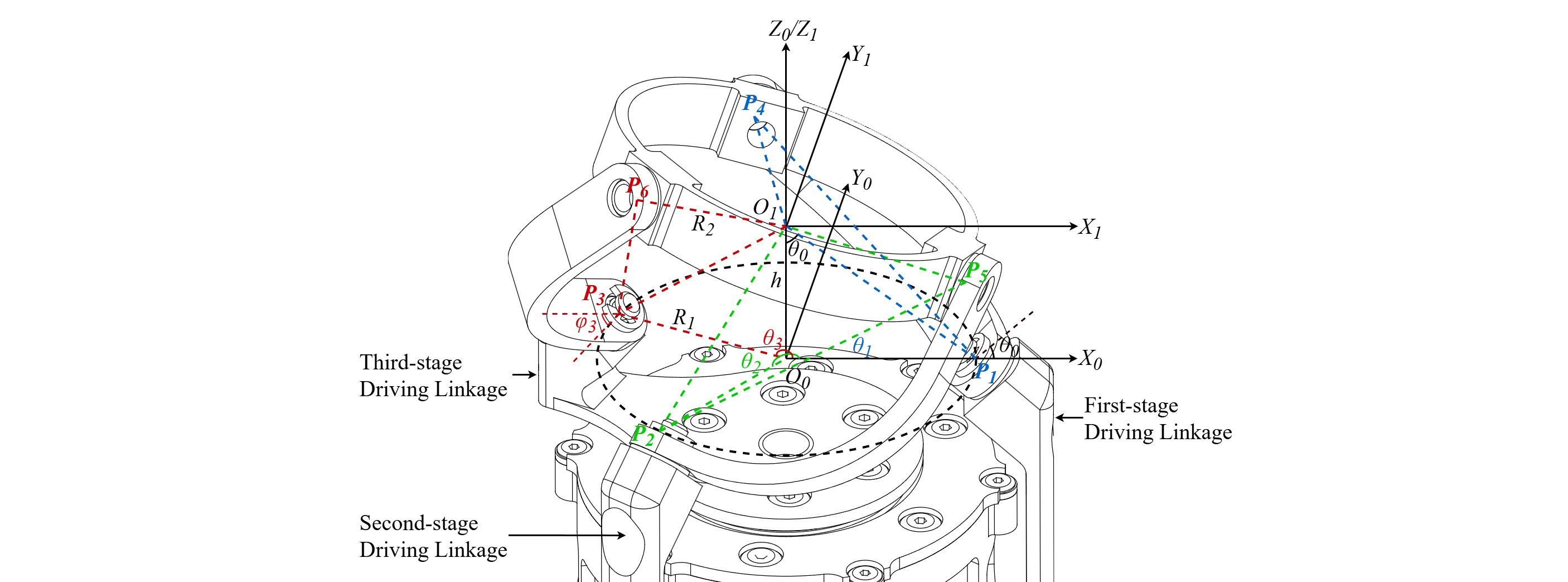

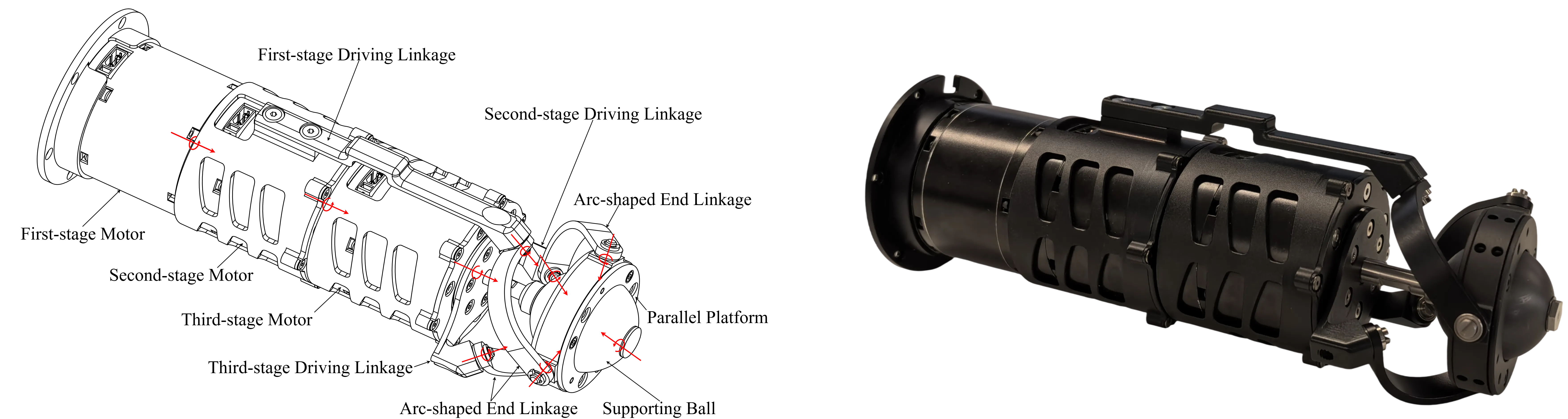

ByteWrist is illustrated in Fig. 1a, which is driven by three stage motors. The output of the first-stage motor is connected to the first-stage driving linkage, which is further linked to the parallel platform via an arc-shaped end linkage. Meanwhile, the second-stage motor is mounted inside the first-stage driving linkage, its output connects to the second-stage driving linkage, which is also linked to the parallel platform through an arc-shaped end linkage. Similarly, the third-stage motor is fixed within the second-stage driving linkage, with its output attached to the third-stage driving linkage that connects to the parallel platform via an arc-shaped end linkage.

All three stage driving linkages and arc-shaped end linkages, as well as arc-shaped end linkages and parallel platform, are connected via revolute pairs. All these six revolute pairs are oriented toward the center of the parallel platform.

To enhance the stiffness of the parallel platform, a supporting ball is mounted at its center and connected to the platform via a spherical joint. By controlling the movement of three stage motors, the end parallel platform can achieve precise RPY motion.

As illustrated in Fig. 1b, the prototype of ByteWrist adopts Quasi-Direct Drive based actuators manufactured by RobStride Dynamics.